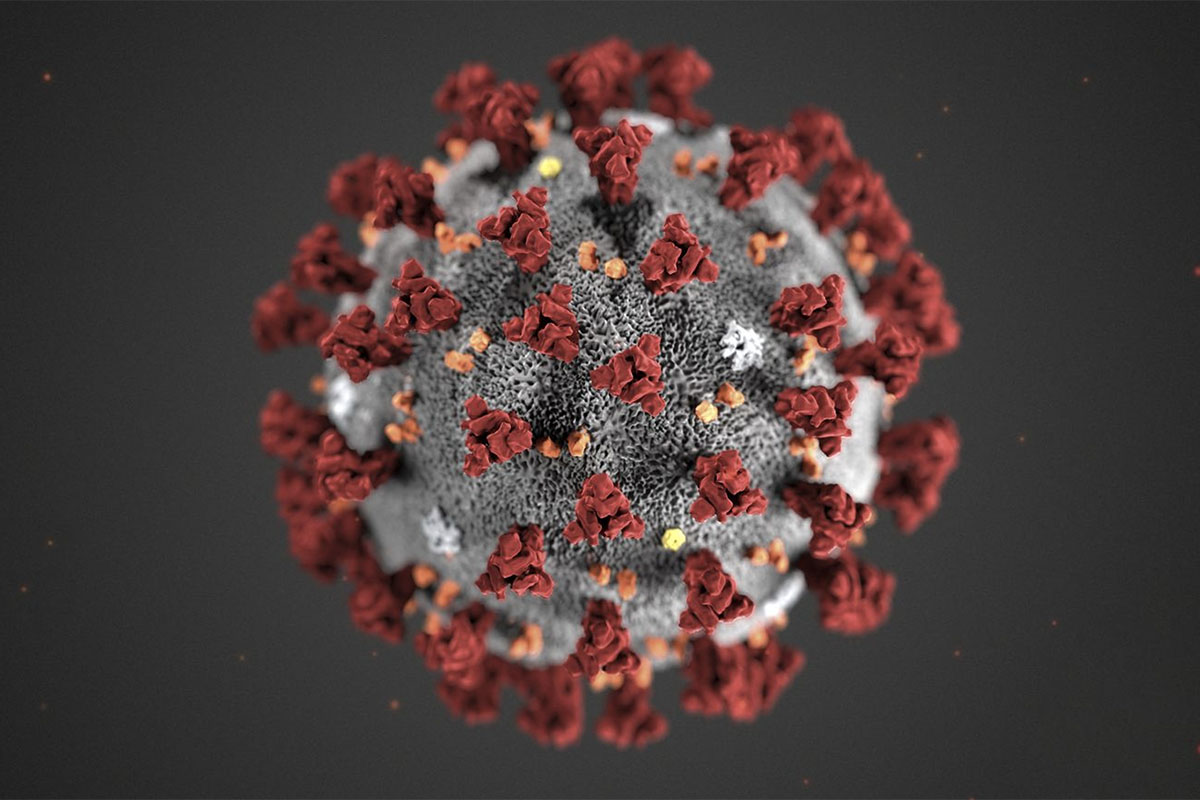

Covid-19 is flailing around. Awareness of our medical care is changing radically right now. Public life is largely at a standstill to slow the spread of Covid-19. Hospitals and general practitioners lack respirators and other personal protective equipment.

Manufacturers of diagnostic, pharmaceutical and medical technology products are working at full speed to provide hospitals, medical staff, general practitioners and thus patients with medical equipment, tests and personal protective equipment. The members of the GHA-German Health Alliance are also committed to fighting the coronavirus pandemic and mastering the immense challenges associated with it. Siemens Healthineers, B. Braun, Bayer, Boehringer Ingelheim, Dräger, MEIKO and Merck supported the fight against Covid-19 on site in China at an early stage with donations in kind and cash.

GHA members ATMOS, B. Braun, Dräger, Getinge, Protec and Zeppelin have observed a significant increase in demand for their products from around the world since the beginning of 2020. For all GHA members, the best possible protection of employees is a top priority in their daily work. As a result of this duty of care, visits to clinical facilities have been minimized and meetings are held by telephone or video conferencing. Production is often split into two shifts to prevent employees from meeting each other. “By separating our employees in terms of time and space, we can avoid crosscontamination and thus ensure production,” emphasizes Maik Greiser, Managing partner at ATMOS.

Like all medical device manufacturing GHA members, Getinge takes its responsibility very seriously to support medical facilities in patient care and provide them with the necessary equipment. Since January 2020, Getinge has seen increased global demand for ventilators, ECMO / ECLS (extracorporeal Membrane oxygenation/extracorporeal life support) devices and advanced hemodynamic monitoring products and expects further growth. To meet demand for ventilators, Getinge announced on March 17 a temporary production increase of ventilators of 60% compared to 2019 at its manufacturing facility in Solna, Sweden. There is a close dialogue with suppliers and no major disruptions have occurred so far. Due to global prevention, travel and transport restrictions, effects on suppliers and the entire logistics chain cannot be ruled out.

Drägerwerk AG & Co. KGaA has also considerably expanded its production capacity in recent weeks. The production facilities for respiratory masks in Sweden and South Africa are working at full capacity and are running around the clock. In Lübeck, Dräger currently produces almost twice as many respirators as before. Dräger has received major orders from the German Federal Ministry of Health to supply ventilators and monitors. And orders are also coming in from abroad. On March 18, for example, the company shipped over 100 ventilators from Germany to Italy. Dräger intends to maintain its service on site in hospitals for as long as possible to maintain or restore the functionality of the products. The company is working flat out to expand its production capacities even further. The fact that Dräger invested in a future-oriented factory with state-of-the-art industrial production methods several years ago is paying off here. Innovative work organization and time models have been agreed with the employees, which provides the necessary flexibility to respond to the currently very high order volume.

With ATMOS MedizinTechnik GmbH & Co. KG the production is also running at full speed, as product groups such as suction and drainage systems, e.g. the worldwide first digital thoracic drainage system, can save lives in the corona crisis. Machine ventilated patients require a respiratory suction device or even a thoracic Drainage system. “Here we are making a system-relevant contribution to the fight against Covid-19,” said Greiser. Since the beginning of March ATMOS has been registering increased demand from all over the world. The number of orders from the product range of medical suction systems (small suction units, emergency suction units, flowmeters and thoracic drains) has doubled in the first quarter of 2020 in percentage terms. The Federal Ministry of Health supports ATMOS in its production to combat Covid-19. In a letter dated March 23, the Federal Ministry of Health requests suppliers to secure and maintain the production capacities of ATMOS by further supply. “The coronavirus is considered a major health risk and the German government is taking decisive measures to stop its future spread and to strengthen the health services in every respect in order to be able to treat patients as necessary. The German government therefore asks for support for measures to halt the future spread of coronavirus” can be read there.

B.Braun Melsungen AG faces an increased demand for products for disinfection and hygiene as well as personal protective equipment, but also for products for safe infusion and drug therapy, anesthetics, infusion and syringe pumps, acute dialysis machines and invasive pressure measurement. “Even in these difficult times, we are doing everything in our power to support our customers so that the treatment of patients worldwide remains guaranteed. This is a particular challenge in the current situation of the corona pandemic,” says Pierre Nasser, International Sales Manager at B. Braun. For the products in the field of personal protective equipment (face masks, head hoods, surgical gowns), which B.Braun does not manufacture itself, supply cannot be guaranteed at present. In the area of surgical and examination gloves, which are sourced from Asia, continuous incoming goods can be recorded. B.Braun has increased the forecast for the entire calendar year by a maximum feasible 20%. There may always be short-term supply bottlenecks and deliveries of comparable product variants.

Products for hand and surface disinfection are manufactured in-house at the plant in Sempach, Switzerland. Here, too, production capacities have been increased by approx. 20% by means of layer construction and a reduction in the number of variants. This will ensure the supply of existing customers in the hospital market and the outpatient sector. Security of supply in anesthesia and intensive care medicine is a high priority for B.Braun. For the portfolio of safe infusion and drug therapy products (medical and pharmaceutical products), production capacity utilization is currently sufficient to cover demand. Production of infusion and syringe pumps and acute dialysis machines is running at high pressure. However, weekly quotas must be allocated for deliveries, which leads to delays in delivery, explains B.Braun.

At one of our smaller medium-sized members, the manufacturer of digital X-ray systems Protec GmbH & Co. KG, production is running at full capacity. Protec also attaches great importance to the protection of its employees and has initiated internal insulation measures. “The demand for mobile digital X-ray systems from our Proslide line for the emergency area is currently particularly high. It has increased fourfold in Europe and internationally. Although we have proactively scheduled more components and increased our inventory since the end of February, these excess stocks of mobile systems have already been sold out again, and there are still sufficient stocks of our lung stand systems for stationary installation,” explains Björn Salwat, Commercial Director at Protec. As a manufacturer of systemrelevant products for examination purposes, Protec is currently still well supplied. Nevertheless, extended delivery times are to be expected. “Fortunately, we have not had any total failures in the supply chain so far. In the Asian region, component production is already getting off to a good start again, albeit not to the same extent as before. However, our northern Italian suppliers are having major problems,”

Salwat emphasizes.

The GHA member Zeppelin Mobile Systeme GmbH is one of the market leaders as a one-stop system supplier for mobile medical accommodation and supply systems, especially for highly sensitive areas such as intensive care or isolation wards. The company offers turnkey products with complete medical technology. These systems can be used as extensions for existing hospitals or completely isolated from any existing infrastructure. During the last two weeks, the demand density was correspondingly high due to the corona crisis. As a result, Zeppelin’s inventories are currently no longer available. Despite the current restrictions, Zeppelin has once again increased its capacities and shortened its delivery time. The fastest possible delivery time for complete Systems is currently two months from order. However, this situation is currently changing daily due to incoming orders and also due to the breaking off of supply chains.

“Nevertheless, a delivery time of 2-3 months is currently too long for many customers,” says Zeppelin sales manager Alexander Lutz. “Firstly, they ignore the fact that this problem will accompany us for much longer and secondly, that delivery times will not improve in the coming months. Now it is taking its revenge that governments have ignored the issue of disaster preparedness for years”. The current portfolio, on which Zeppelin is concentrating its efforts in the fight against the pandemic, consists of three main systems: A small, quickly relocatable isolation ward with 6 intensive care beds or up to 12 normal patient beds, an intensive care unit in a container with 4 intensive care beds (multiplyable) and a 40- 50 bed hospital, tent based, with intensive and high dependency beds, as well as other hospital areas and supply units.

In addition to medical technology companies, pharmaceutical companies are also involved among the members of GHA. For example, Johnson & Johnson Medical GmbH and its pharmaceutical division Janssen have started the development of a vaccine candidate against SARS-CoV-2 virus and are collaborating on the review of a database of existing antiviral therapies. Bayer AG has joined forces with other manufacturers in the COVID-19 Therapeutics

Accelerator Initiative, which was established by the Bill & Melinda Gates Foundation to open up its extensive library of compounds and to find and develop effective new drugs to combat COVID-19. Bayer is also expanding its capacity to offer large quantities of PCR tests in its laboratories, for example 10,000 tests per day in Wuppertal. The coronavirus pandemic hits everyone equally hard and unexpectedly and is particularly bad for each individual affected. The GHA members are facing this unprecedented challenge with great commitment and success – for all of us. In the short term, every end customer and trader in the healthcare system should act proactively, Salwat calls for. “Anyone who now hesitates further with necessary orders will soon be even further behind. Because demand will continue to rise, production will fall behind and delivery times will become even longer,” warns Salwat.